Centrifugal pumps are a sub-category of the different kinds of mechanical pumps. Centrifugal pumps work on the principle of conversion of rotational kinetic energy into flowing energy of the fluids. The rotational kinetic energy of the centrifugal pump is obtained b the electrical motor whose shaft is connected in common with that of the centrifugal pump. The electric energy is converted into rotational kinetic energy of the motor from which it is again converted into the flow of liquid by the pumping action. We as a company are centrifugal pump manufacturers. We are also into centrifugal pump suppliers and centrifugal pump suppliers.

Description

We offer a variety of centrifugal pumps based on the customer requirements. The different kinds of centrifugal pumps under our portfolio are as follows:

- Dewatering pumps: The dewatering pumps are used for the removing water from any container either it is in the upper level or higher level of container.

- Pressure water pump: These are the centrifugal pumps that help in the motion of the water using pressure power and are used for various industrial and domestic purposes.

- Water circulating pumps: Generally a circulator pump is used for the circulation of gases, liquids or semi fluids. Our water circulating pumps are used for the circulation of both hot and cold water for a cooling system in any industry where there is much heat generating processes going on.

We also provide centrifugal pumps based on the requirements of our client with higher quality standards. Our centrifugal pumps are made of fine stainless steel material and are manufactured with a smoother finish and less friction. Our centrifugal pumps are suitable for water and various other fluids with mild concentration.

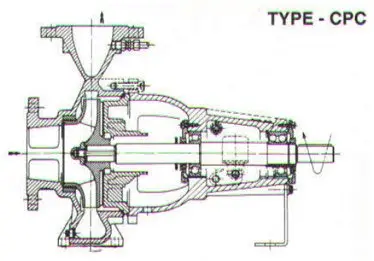

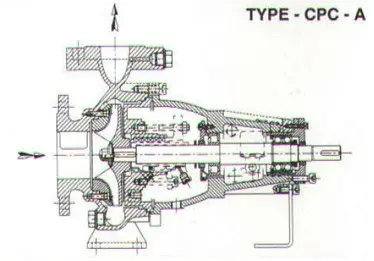

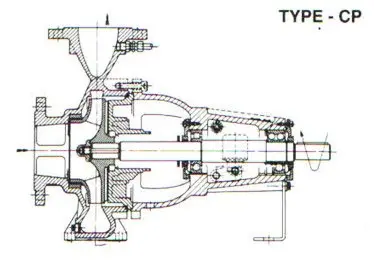

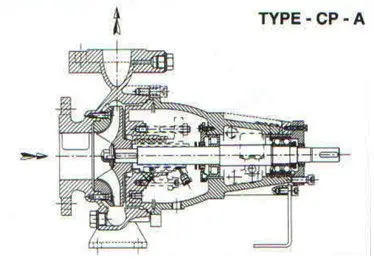

Centrifugal Process Pump (Mechanical Seal / Gland Fitted) Type : “ CP “ AND “ CPC”

Application: Various application include transfer and circulation pump for cold and hot water system, marine installation, fire fighting application, irrigation, agriculture and etc…

Design:

The centrifugal pump – CP is a end suction, horizontal, backpull out pump in accordance with DIN24255 and CPC & CPC-A with accordance DIN-24256 / ISO-2858.

Seal Arrangement: Either a soft packed gland or Mechanical seal can be used.

There are two types basically CP and CPC. The different applications of these kinds of pumps are into hot and cold-water flow, marine applications, fire fighting applications and irrigation purposed for agriculture.

We provide different variants of centrifugal pumps according to the customer’s needs and preferences. The centrifugal pumps come in different designs and have several features. The centrifugal pump – CP is an end suction, horizontal, back pull out pump. The pumps use different seal Arrangements. The pumps use either mechanical seal or softly packed gland can be used. The pumps facilitate Stuffing box cooling for temperature, Ranging from 160*C to 200*C. These centrifugal pumps are made of stainless steel and have a smooth surface. A pump is just the ideal one for water and even the other fluids. We at Active Engineering Company are the best centrifugal pumps manufactures.

Characteristics

- The chemical process Pump “CPC” and “CP” is widely used for chemical, petrochemical industries.

- Maximum Capacity : 400m3/Hr.

- Head : 150 Mtr.

- Pressure : 16 bar

- Temperature : 200*C

- M.O.C. – C.I. CS, SS304, SS-316 and Other Alloys.

- Sealing Type : Mechanical Seal Fitted and Gland Fitted Impeller Type: Close and Semi Open

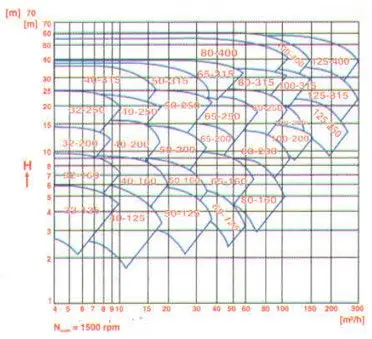

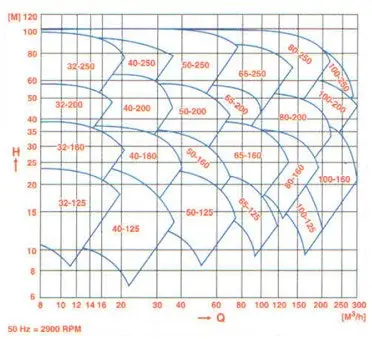

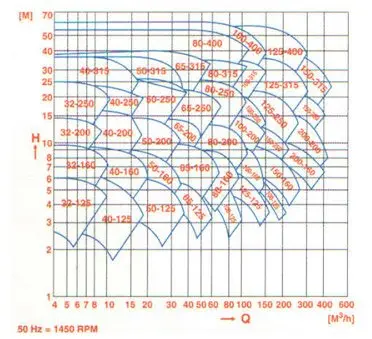

Range

- Maximum Flow: 400m3/hr.

- Maximum Head: 100 meter

- Maximum Pressure: Up to 16 bars

- Maximum Temperature: 200* C

- Standard material: C.I., C.S., SS-

- 304, SS-316, Bronze & Gun Metal

- Shaft & Shaft Sleeve: Stainless Steel

- Impeller Type: Closed / Semi Open

Operating Data

- Head : Up to 35 Mtr.

- Flow : Up to 75m3/hr.

- Sealing : Soft Gland and Mechanical Seal.

- Required Suction : Negative or Positive

- Maintenance : Low maintenance

- Service : Easy

- M.O.C. : C.I., SS 304, SS 316, Gun Metal and other alloy.

Mechanical Seal Option

- STD. (Carbon Vs Silicon Carbide / Single Spring or Multi Spring)

- Other (Carbon Vs TC / Single Spring or Multi Spring )

- CCT (Silicon Carbide Vs Silicon Carbide / Single Spring or Multi Spring)

Download Performance Table Chart

Pump & Seals Broucher

Pump & Seals Broucher