A Single spring seal is used to handle the fluids like gunk and muck. Single spring seal is used in different companies for different operation related to sludge and water. With the help of this seal a pump can transfer sludge and water with no any leakage. We construct the seals with a large variety of suitable raw material. We believe in providing the highest quality products to our valuable clients, because it helps in building a good relationship between customer and dealer. The selection of the Single spring seal manufacturers for its construction is determined by the liquid seal and space limit. The benefit of this type of production is the openness of the design makes your product a non clogging element of the spring seal.

Description

We at Active Seals are the Mud Pump Manufacturers

We are the most experienced and talented single spring seal suppliers in Ahmadabad and we always believe in serving the best quality product on time. We use advance material along with the unparalleledlayout concept, which makes our seal long lasting. Even we are the single spring seal suppliers in thiscompetitive field of business, we manufacture the innovative product and export in other countries. Our experienced and talented team develops and design diverse of seal with innovative ideas, which helps our customer in rotating equipments like pumps, blowers and mixers. The Active engineering company is here to assist you in your reliability products so that you can achieve world class performance.

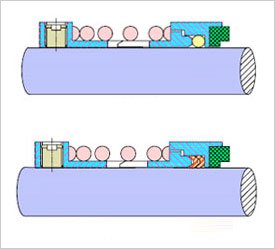

20 Years ago, generally pump shafts were sealed via rings of elastic packing, squashed by a packing gland, but this sort of shaft seal needs a fair quantity of leakage just to lubricate the packing and keep it chill. Then the progress of the “mechanical seal,” which fulfil the work of preventive product leakage in the order of the pump shaft with twoplane surfaces (one stationary and one revolving).

Still this sort of mechanical seal faces also needfew amount of leakage across the faces, to create a hydrodynamic film, this leakage usually evaporates and is not visible. Mainly pump shafts today are preserved by means of the mechanical seals. However, because of the fineelements used for this new sealing technique, mechanical seal failures are the biggestreason of pump down time. We have a team of the skilled workers, which check the quality of the product during the production and after the production, so you don’t need to worry after taking our services. We provide the high quality products with cost effective prices, which is the most important factor for anybody. Even we design the products according to the unique requirements of the customers, because customer satisfaction is our only priority. So let us change your mechanical seal with our new modernized single spring seal.

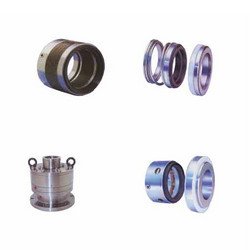

Single Seal

We have developed the wide range of the single seal with high tensile strength. It consists of sturdy construction. It is the abrasion resistant seal. It is made from high grade raw material. It is of flexible type seal.

Metal Single Spring Seal

We offer the metal single spring seal manufactured from finest quality of raw material. It is easy to operate and simple to install seal. It is specially designed to handle the fluids like slurries and sludge. It is widely used in the sewage. The seals are popular for the tolerance. metal single spring seal is also favorable with our valuable clients for higher tensile strength.

Download Performance Table Chart

Pump & Seals Broucher