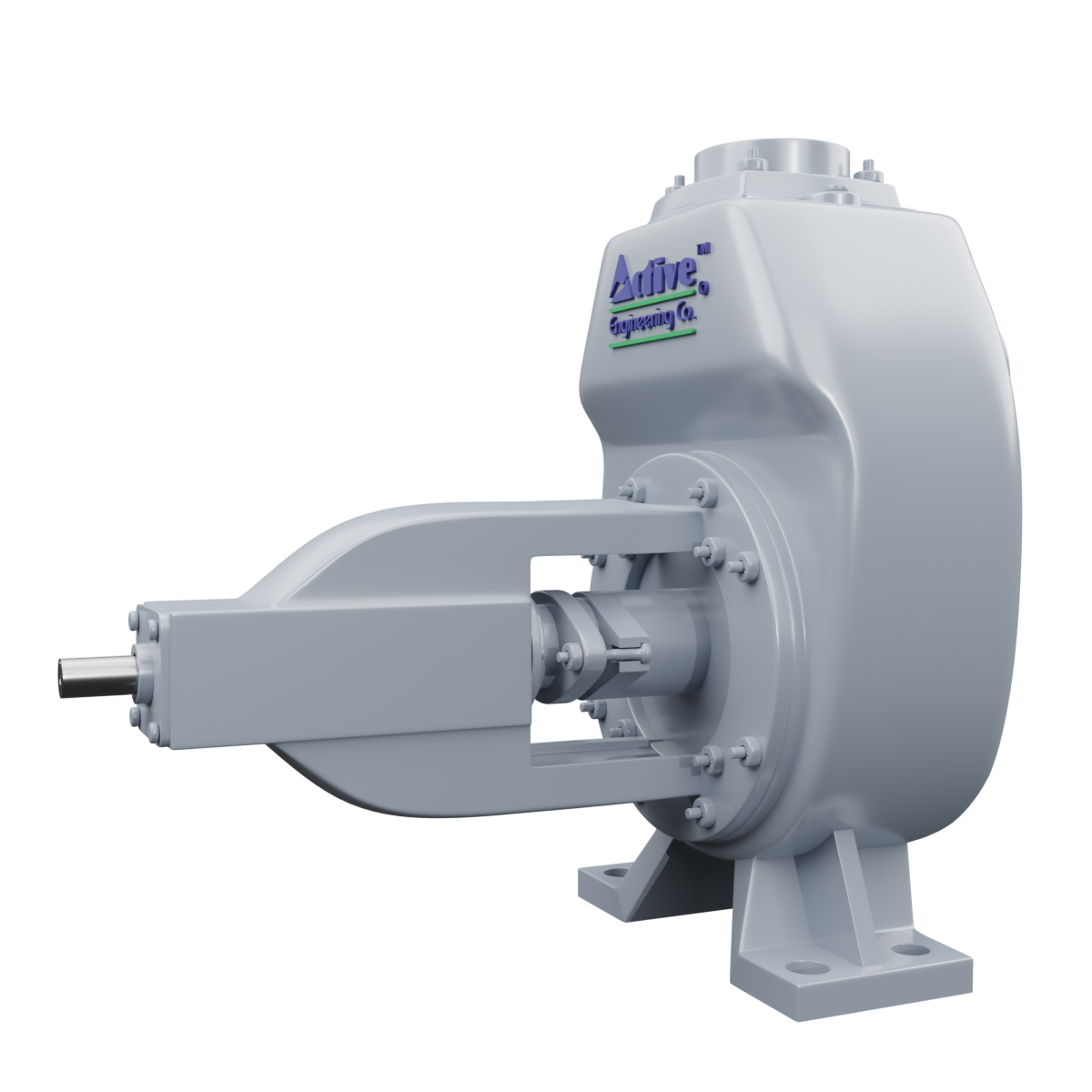

Mud Pump Manufacturers

Mud Pumps is a very important part of the oil well drilling equipment that is used.

It is a large reciprocating pump which is used to circulate the mud which is the drilling fluid on a drilling rig. Active seals provides with a broad range of mud-pumping systems which are well equipped to meet the needs and demands of its customers. The company constantly comes up with improvements and new ideas to move ahead with innovation and cutting edge design. We are the Mud Pump Suppliers who supply the mud pumps of highest quality to circulate the semi-solid or the fluid without any hassles during its operation.

Description

We at Active Seals are the Shaft Seal Manufacturers

We manufacture these products and do not just resell them. The products are manufactured from high quality raw materials. It is of sturdy construction and provides with characteristics such as high abrasion. We provide with self-priming pumps, abrasion resistant which provide with better results for the pumping out of the settled sludge. The pumps are time-tested as well as high-pressure mud-pumping systems. All the pumps are equipped to handle any kind of operation in an expert manner.

The company has come up with a huge range of pumps that are well suitable for pumping of muddy water as well as the sewage water, polluted liquids and the solids. Not only all these, the pumps can also be used to clear the water used in the swimming pools. The pump manufactured by Active Seals comes with a head of up to 35 metres and flow up to 75 m3/hour.

The sealing of the pumps is done with soft gland and mechanical seal. The suction required can be both negative and positive depending on the user’s need. Even though the pump is a required extensively, it requires low maintenance and the service is very easy to get. The pump is available in various M.O.C. such as C.I., SS 304,SS 316, Gun Metal and various other alloys as well depending on the needs of the customer.

Characteristics

- Perfect Sealing Assured by High Efficiency and Quality.

- Mechanical Sealing that means zero leakage and 100% Vacuum

- Creation Back Pull Out Design Drive Option of Ele. Motor, Coupled or belt drive versions

- Bearing greased for life, Save external lubrication

Applications

- Water Transfer

- Chemical Transfer

- ETP Water

- Filter Press

- Rain Water

- Cooling Water

- Petrol, Kerosene, and Other Solvents.

- Dewatering Swamp

- Trenchs & Basements Effluent Treatment Plants

- Swimming Pools, Marine Application Transfer for Petrol, Diesel, Kerosene, Sprits, Gasoil’s etc…

Operating Data

- Head : Up to 35 Mtr.

- Flow : Up to 75m3/hr.

- Sealing : Soft Gland and Mechanical Seal.

- Required Suction : Negative or Positive

- Maintenance : Low maintenance

- Service : Easy

- M.O.C. : C.I., SS 304, SS 316, Gun Metal and other alloy.

Mechanical Seal Option

- STD. (carbon Vs Ceramic / Tc with NBR elastomeric)

- CCV (Carbon Vs Ceramic / Tc with Viton elastomeric)

- CCT (Carbon Vs Ceramic / Tc with PTFE elastomeric)

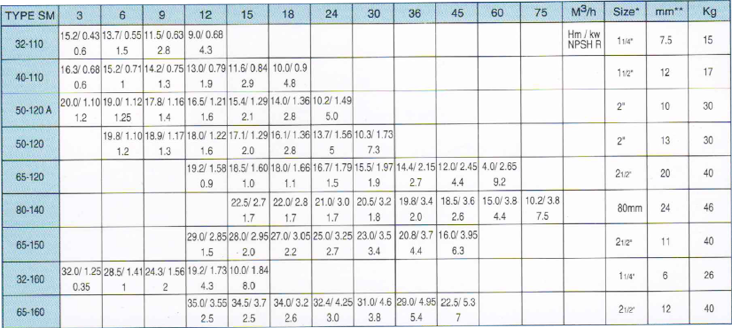

Download Performance Table Chart

Pump & Seals Broucher

Pump & Seals Broucher

For 50Hz=2900RPM

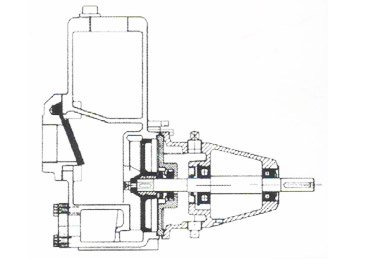

Drawing